Pushing the Limits of Construction Technology: 3D Printing Takes Center Stage

The field of construction is experiencing a revolutionary transformation, thanks to the advent of 3D printing technology. Traditional construction methods are being challenged as 3D printing pushes the limits of what is possible in the industry. In this blog post, we explore the groundbreaking applications and advancements of 3D printing in construction, highlighting how it is revolutionizing the way we design, build, and shape the world around us.

Unleashing Design Freedom

One of the most significant advantages of 3D printing in construction is the unparalleled design freedom it offers. Traditional construction often imposes limitations on architectural creativity due to the constraints of materials and construction techniques. However, 3D printing allows architects and designers to break free from these restrictions, enabling the realization of complex and unconventional structures.

With 3D printing, it is possible to create intricate geometries, organic shapes, and custom designs that were previously impractical or costly to construct using traditional methods. This newfound design freedom opens up endless possibilities for architects and engineers to create structures that are not only visually striking but also optimized for functionality, energy efficiency, and sustainability.

Speed and Efficiency in Construction

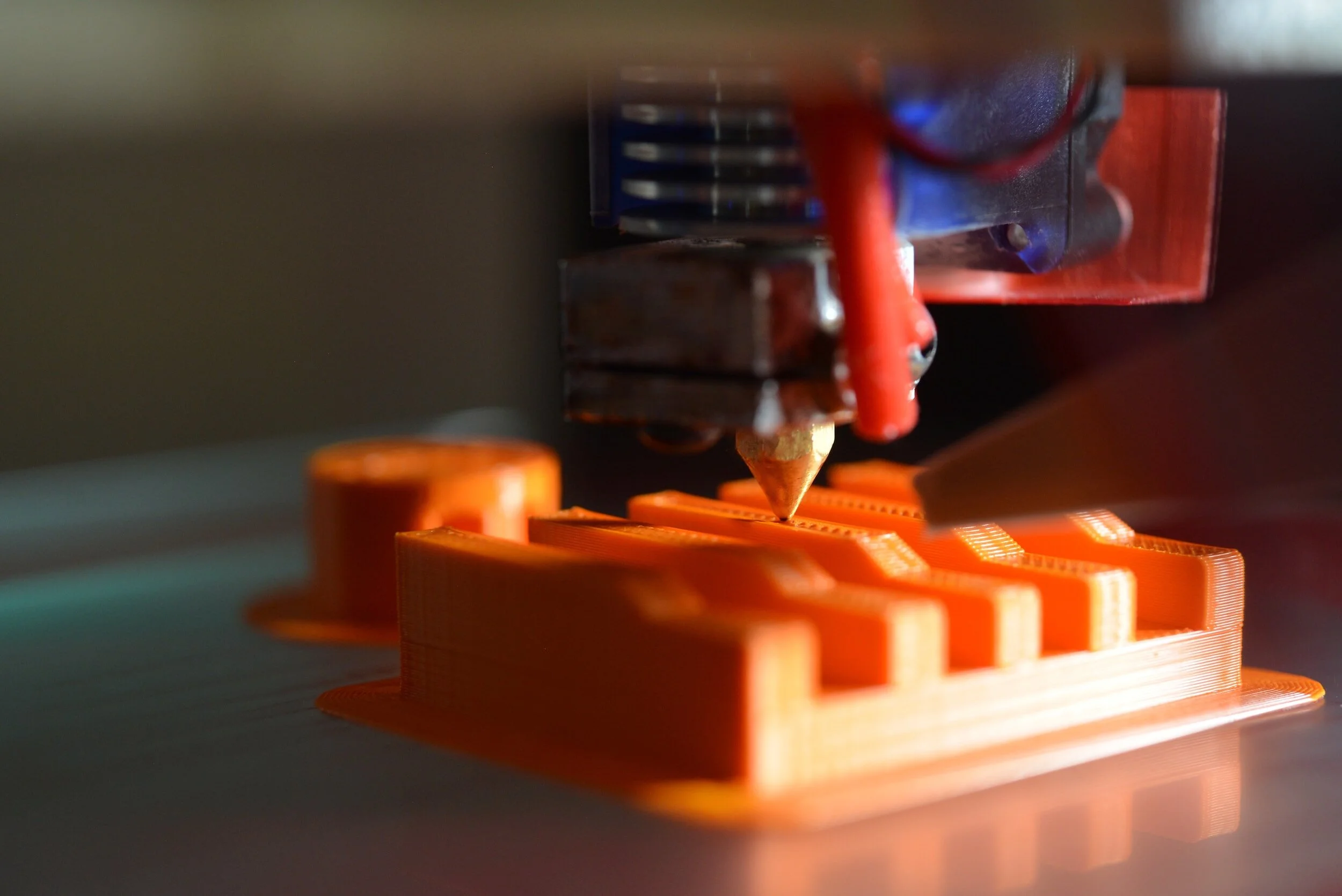

3D printing also revolutionizes construction by drastically reducing the time and labor required to build structures. Traditional construction projects often involve numerous labor-intensive processes, including cutting, shaping, and assembling individual components. In contrast, 3D printing allows for the rapid, continuous extrusion of construction materials, significantly streamlining the building process.

By automating much of the construction process, 3D printing eliminates many manual tasks and reduces the potential for human error. Additionally, the precision and accuracy of 3D printing technology ensure consistent quality throughout the construction process, minimizing the need for rework and enhancing overall project efficiency.

Sustainable and Cost-Effective Solutions

The integration of 3D printing in construction also offers promising prospects for sustainable and cost-effective solutions. The ability to precisely control material usage during the printing process results in minimal waste generation, reducing environmental impact. Furthermore, 3D printing allows for the use of alternative and sustainable materials, such as recycled plastics or bio-based materials, offering eco-friendly alternatives to traditional construction materials.

From a cost perspective, 3D printing can potentially reduce construction expenses by optimizing material usage, minimizing labor requirements, and shortening project timelines. This technology has the potential to revolutionize affordable housing initiatives and disaster relief efforts by providing rapid, cost-effective construction solutions in areas where traditional methods may be challenging or impractical.

Impressive Applications and Case Studies

Numerous impressive applications and case studies showcase the potential of 3D printing in construction:

1. The Netherlands: The "3D Print Canal House" project in Amsterdam, Netherlands, exemplifies the power of 3D printing in creating innovative architectural structures. The project uses large-scale 3D printers to construct a fully functional, multi-room canal house, showcasing the versatility and scalability of 3D printing technology.

2. The Middle East: Dubai is known for its ambitious architectural projects, and it is also at the forefront of adopting 3D printing in construction. The city has set a target of 25% of new buildings being constructed using 3D printing technology by 2030. The Dubai Municipality has already successfully completed projects such as the "Office of the Future" and the "Dubai 3D Printing Strategy."

3. China: Construction of houses, apartments, and even entire villages are planned by multiple scientists and civil engineers to be 3D printed. For example, the company WinSun has built multiple 3D printed houses using a large-scale 3D printer and recycled construction waste. These projects demonstrate the potential for 3D printing to address housing shortages and create sustainable living solutions.

Challenges and Future Outlook

While 3D printing in construction holds immense promise, several challenges need to be addressed for its widespread adoption:

1. Regulatory Frameworks: As 3D printing technology advances, there is a need to establish standardized regulations and building codes to ensure safety, quality, and compliance with existing construction norms.

2. Material Development: Continued research and development are essential to improve the range and quality of construction materials suitable for 3D printing. Advancements in material science will further enhance the structural integrity, durability, and environmental sustainability of 3D printed structures.

3. Integration with Traditional Construction: Integrating 3D printing seamlessly with traditional construction methods poses logistical and technical challenges. Developing hybrid construction approaches that combine the benefits of both traditional and 3D printing techniques is an area of active exploration.

Conclusion

3D printing is undoubtedly pushing the limits of construction technology, revolutionizing the industry with its design freedom, speed, sustainability, and cost-effectiveness. The ability to create complex structures with precision and efficiency has the potential to transform the way we build and shape our world.

As 3D printing continues to evolve, addressing regulatory, material, and integration challenges will be crucial for its widespread adoption in the construction industry. However, the remarkable applications and case studies already in existence highlight the immense potential of 3D printing to create sustainable, innovative, and architecturally stunning structures.

With ongoing research and collaboration between architects, engineers, material scientists, and regulatory bodies, the future of 3D printing in construction looks promising. As the boundaries of what is possible in construction continue to be pushed, we can anticipate a future where 3D printing plays a significant role in shaping our built environment and propelling the industry into a new era of creativity, efficiency, and sustainability.